What are the advantages and disadvantages of a 4 jaw chuck

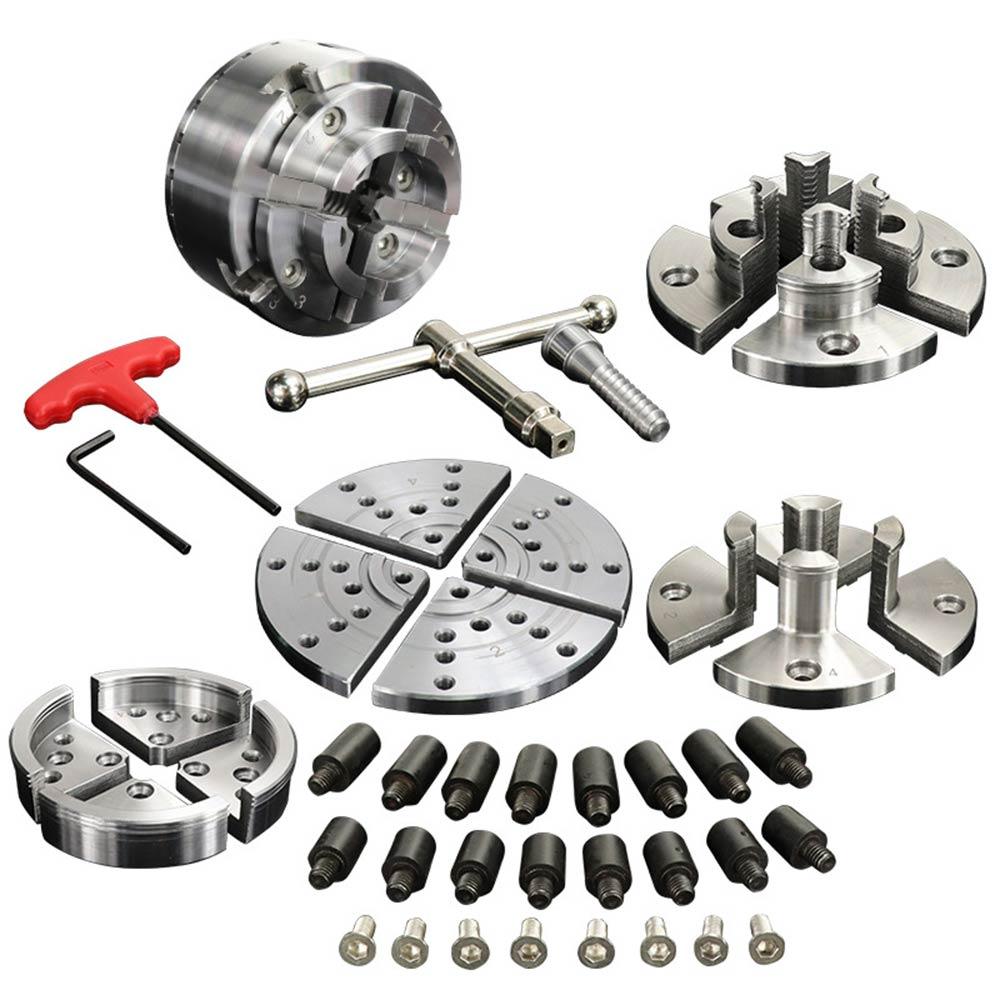

A 4-jaw chuck is a type of chuck commonly used in lathe machines for holding and securing workpieces. Here are the advantages and disadvantages of a 4-jaw chuck:

Advantages of a 4-Jaw Chuck:

1. Versatility: A significant advantage of a 4-jaw chuck is its versatility. Unlike a 3-jaw chuck that is primarily designed for cylindrical workpieces, a 4-jaw chuck can securely hold a wider range of shapes, including irregularly shaped or non-symmetrical workpieces. The independently adjustable jaws allow for precise gripping and centering of various workpiece geometries, making it suitable for more complex machining tasks.

2. Centering Flexibility: A 4-jaw chuck offers greater flexibility in centering the workpiece. Each jaw can be adjusted independently, allowing for fine control over the centering process. This is particularly useful when working with eccentric or off-center workpieces. By adjusting the jaws individually, you can achieve proper alignment and balance, ensuring accurate machining operations.

3. Secure Grip: The four jaws of a 4-jaw chuck provide a more secure grip on the workpiece compared to a 3-jaw chuck. The additional jaw provides increased contact points, distributing the gripping force more evenly. This enhanced grip is advantageous when working with larger or heavier workpieces that require more stability and rigidity during machining operations.

4. Eccentric Turning Capability: One of the notable advantages of a 4-jaw chuck is its ability to perform eccentric turning operations. By adjusting the jaws at different positions, you can intentionally offset the workpiece from the lathe's spindle axis. This allows for the creation of eccentric features, such as off-center holes or turned profiles. Eccentric turning can be useful for various applications, including creating off-center shafts or adding design elements to woodworking projects.

5. Customization: Another benefit of a 4-jaw chuck is the ability to customize the gripping configuration. You can adjust the jaws to accommodate specific workpiece requirements. For example, you can use the chuck to grip irregularly shaped objects, square stock, or even hold workpieces internally by gripping on the inside diameter. This flexibility is advantageous when working with unique or specialized projects.

Disadvantages of a 4-Jaw Chuck:

1. Setup Time: Compared to a 3-jaw chuck, setting up a 4-jaw chuck can be more time-consuming. Since each jaw needs to be adjusted individually, it may take additional time and effort to achieve proper centering and alignment of the workpiece. This can be especially true for beginners or those less experienced with using a 4-jaw chuck.

2. Increased Complexity: The presence of four independently adjustable jaws adds complexity to the chuck's operation. It requires more skill and precision to properly adjust and tighten each jaw to ensure even gripping force and alignment. Beginners may find it more challenging to work with a 4-jaw chuck compared to a 3-jaw chuck due to the increased complexity and the need for accurate adjustments.

3. Cost: 4-jaw chucks tend to be more expensive compared to their 3-jaw counterparts. The additional moving parts and adjustability contribute to the higher cost. If you primarily work with cylindrical workpieces and do not require the extra flexibility and features provided by a 4-jaw chuck, the added expense may not be justified.

4. Learning Curve: Using a 4-jaw chuck effectively requires a certain level of skill and experience. The process of adjusting the jaws independently and achieving proper centering can be challenging for beginners. It often takes practice and familiarity to master the fine adjustments needed for accurate machining operations.

5. Maintenance: The increased number of moving parts in a 4-jaw chuck can result in more maintenance requirements. The jaws, screws, and other components may need periodic cleaning, lubrication, or adjustment to ensure smooth operation. Regular inspection and maintenance are necessary to keep the chuck in optimal working condition.

In summary, a 4-jaw chuck offers greater versatility, centering flexibility, and secure gripping capabilities compared to a 3-jaw chuck. However, it comes with some drawbacks, including increased setup time, complexity, and cost. Consider your specific machining needs, the types of workpieces you commonly work with, and your level of experience to determine if a 4-jaw chuck is the right choice for you.